DESIGN STANDARD

General Design

: API 602 / BS 5352

Testing

: API 598 / BS 6755 (Part-1)

PRODUCTS RANGE

Size

: ½” to 2” (DN15 - DN50)

Type

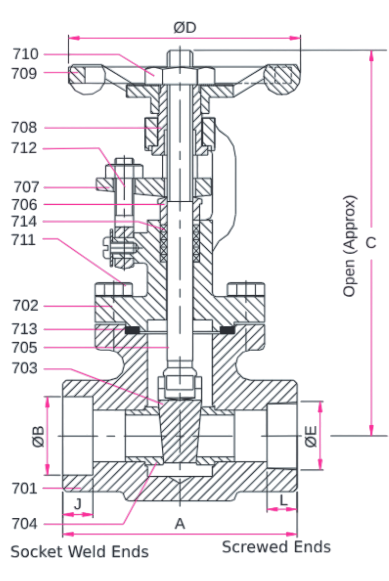

: Bolted Bonnet, OS & Y, Flexible Wedge.

Rating

: Class 800 & Class 1500.

Face to Face

: AS SHOWN

Pressure & Temperature Rating

: Screwed Ends to BSP/BSPT/NPT

Flange Standard Conformity

: Socket Weld Ends to ANSI B16.11

SALIENT FEATURES

- Valves meets to API 602 / BS 5352 design requirements.

- Body full bore to API 602 / BS 5352 ensures streamlined flow hence no pressure drop.

- Body guided wedge ensures positive seating and eliminates side thrust & flexible wedge ensure tight shut-off.

- Graphite packing ring, top & bottom rings are braided graphite its ensures effective stem sealing.

- Hardened seats minimizes on line erosion & provide maximum service life.

- Variety of materials available to suit special application requirement.

| PART NO | PART NAME: | MATERIAL SPECIFICATION | ||||

| 701 | Body | A 105 | F 304 | F 316 | ||

| 702 | Bonnet | A 105 | F 304 | F 316 | ||

| 703 | Wedge | AISI 410 | AISI 304 | AISI 316 | ||

| 704 | Seat Rings | AISI 410 | AISI 304 | AISI 316 | ||

| 705 | Spindle | AISI 410 | AISI 304 | AISI 316 | ||

| 706 | Gland Bush | AISI 410 | AISI 304 | AISI 316 | ||

| 707 | Gland Flange | A105 | F 304 | |||

| 708 | Yoke Sleeve | ASTM A 439 Gr. D2/AL-BRONZE | ||||

| 709 | Hand Wheel | Cast Steel / M.I. | ||||

| 710 | Hand Wheel Nut | Gr. 2h | ||||

| 711 | Stud & Nut | B7/2H | B8/ 8 OR B7/2H | |||

| 712 | Eye Bolt & Nut | B7/2H | B8/ 8 | |||

| 713 | Gasket | SPW S.S. 304/316 With CAF / GRAFOIL | ||||

| 714 | Gland Paking | Graphite Asbestos Inhib, & Inconel Wire Rein. | ||||

DIMENSION TABLE 800#

| SIZE | A | C | ØD | SCREWED ENDS | SOCKET WELD ENDS | ||||

| IN INCH | IN MM | ØE | L | MAX. | MIN. | J MIN. | |||

| ½” | 15 | 85 | 165 | 90 | ½” | 13.56 | 22.22 | 21.72 | 9.65 |

| ¾” | 20 | 92 | 176 | 90 | ¾” | 13.87 | 27.56 | 27.05 | 12.7 |

| 1” | 25 | 105 | 198 | 90 | 1” | 17.35 | 34.29 | 33.78 | 12.7 |

| 1½” | 40 | 127 | 278 | 145 | 1½” | 18.38 | 49.15 | 48.64 | 12.7 |

| 2” | 50 | 140 | 298 | 145 | 2” | 19.23 | 61.62 | 61.11 | 15.75 |

DIMENSION TABLE 1500#

| SIZE | A | C | ØD | SCREWED ENDS | SOCKET WELD ENDS | ||||

| IN INCH | IN MM | ØE | L | MAX. | MIN. | J MIN. | |||

| ½” | 15 | 85 | 165 | 90 | ½” | 13.56 | 22.22 | 21.72 | 9.65 |

| ¾” | 20 | 92 | 176 | 90 | ¾” | 13.87 | 27.56 | 27.05 | 12.7 |

| 1” | 25 | 105 | 198 | 90 | 1” | 17.35 | 34.29 | 33.78 | 12.7 |

| 1½” | 40 | 127 | 278 | 145 | 1½” | 18.38 | 49.15 | 48.64 | 12.7 |